Steel quenching is a critical process in metallurgy that plays a significant role in enhancing the properties and performance of steel. Understanding what quenching is and how it works can provide valuable insights into this fundamental technique. Let’s dive into the process of steel quenching!

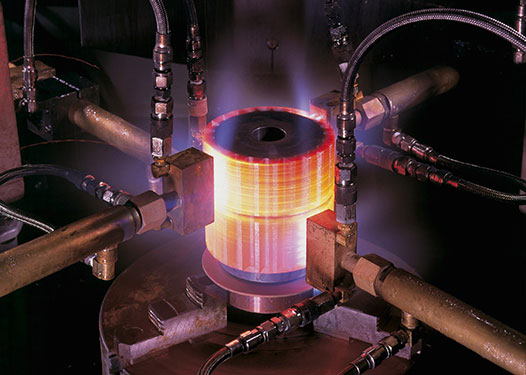

Quenching, also known as hardening, is a heat treatment method used to rapidly cool heated steel to achieve specific mechanical properties. The process involves heating the steel above its critical transformation temperature and then rapidly cooling it in a quenching medium, such as oil, water, or polymer solutions.

The primary objective of quenching is to create a high level of hardness in the steel while preserving its desirable properties. When steel is heated to its critical temperature, the structure undergoes a phase transformation, and the austenite phase is formed. The rapid cooling during quenching prevents the austenite from fully transforming into other phases, resulting in the formation of a hard and brittle microstructure called martensite.

The quenching medium plays a crucial role in the process. The choice of quenching medium depends on the type of steel and desired properties. Water, for example, provides rapid cooling and is suitable for high-carbon steels. Oil and polymer solutions offer slower cooling rates, which are often required for low-carbon and alloy steels. The quenching medium’s temperature, agitation, and specific composition can also affect the final properties of the steel.

Proper quenching requires careful control of cooling rates and uniform cooling throughout the steel. If the cooling rate is too slow, the steel may not achieve the desired hardness, while excessively fast cooling can lead to cracking and distortion. Achieving the optimal cooling rate often requires expertise and precise temperature monitoring.

The quenching process is typically followed by a tempering step. Tempering involves reheating the hardened steel to a specific temperature and holding it there for a designated period. This step helps relieve internal stresses, reduce brittleness, and improve the steel’s toughness and ductility. The tempering temperature and time are carefully controlled to achieve the desired balance of hardness and toughness.

Steel quenching is widely used in various industries, including automotive, aerospace, and tool manufacturing, where hardness, strength, and wear resistance are crucial. By carefully selecting the appropriate quenching parameters, metallurgists and engineers can tailor the properties of steel to meet specific requirements.